How to make a precise punch cutting positioning?

27 February 2025We were delighted to discover that our hollow punches were used to reseal a crankcase paper gasket in an episode of Wheeler Dealer France, broadcast on RMC Découverte.

This episode focuses on the restoration of a Mercedes G-Class.

Gearbox, engine, interior upholstery… Jerry and Aurélien are working hard to restore this famous 4×4 to its former glory. Of course, some original parts are nowhere to be found, and some items such as gaskets and upholstery have to be redone by yourself. In this case, it’s imperative to have the right tools for repairing vintage vehicles, especially circular-cutting tools.

Punch tools are indispensable in car restoration, and are very useful for upholstery work, but in this episode we see how they can be used to reseal an engine crankcase.

To make a paper crankcase gasket yourself, Aurélien first draws the outline of the gasket on the paper, not forgetting the holes for the crankcase fixing screws. Then, using a traditional cutter, he cuts the inside of the joint. Then, he cuts out the screw holes using the BOEHM punching system to ensure a clean, circular cut.

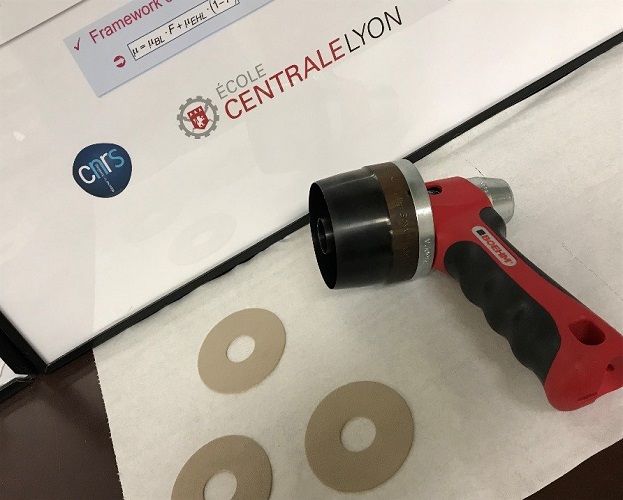

The BOEHM striking tool features a patented ergonomic handle which allows the hand to be offset from the hammer’s striking axis (thus avoiding hand injuries!) and has a mechanism for absorbing vibrations transmitted to the hand. A quick-release locking system allows efficient attachment and removal of punches from their mandrels.

All Aurélien has to do is attach a punch to the handle, corresponding to the diameter of the screw holes. After a few hammer blows, he makes the cuts. Finally, he cuts the outer contours of the joint with a chisel, and Aurélien obtains a new joint identical to the old one, which he has made himself.

Hollow punches can also be used in automotive restoration, not only to cut crankcase gaskets, but also to cut circular gaskets. BOEHM’s range of boxes offers a wide variety of sizes, enabling car restorers to remanufacture gaskets that are hard to find. A multitude of cut-outs is possible thanks to over 140 different diameters that can be combined to make seals in a single operation.

To find out more, click on our page dedicated to Automotive Restoration.

To see the video of the show: